- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: Site Editor Publish Time: 2024-01-03 Origin: Site

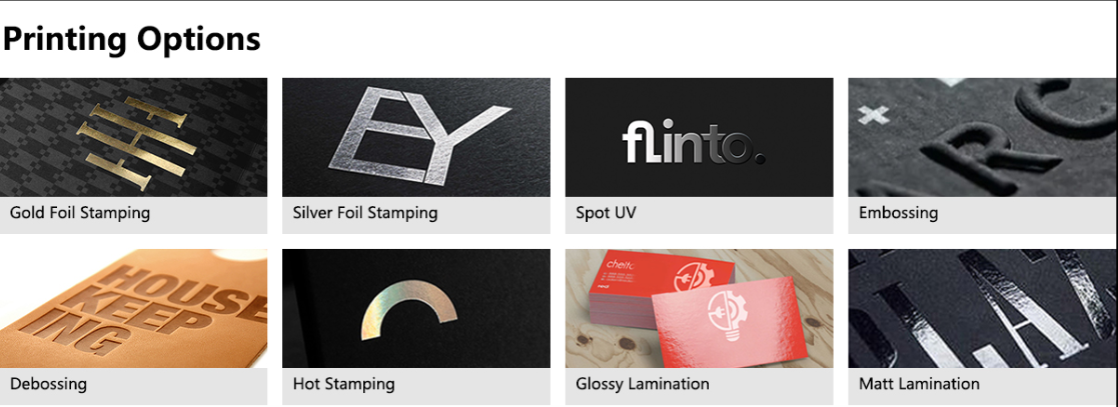

1. Hot stamping

Features: good quality, high precision, clear and sharp image edges, high gloss, bright and smooth patterns. Scope of application: exquisite high-end gift boxes, paper, business cards, invitations, etc.

2. Three-dimensional PU

Features: good texture, beautiful colors, strong three-dimensional effect, high hiding power, chemical resistance, friction resistance, and does not damage the substrate. It has excellent performance when printing fine lines or fonts. Scope of application: packaging boxes, hardcover album covers, molds, signs, electronics, rubber, etc.

3.Flocking

Features: Strong three-dimensional effect, bright colors, soft touch, thermal insulation and moisture-proof, non-linting, friction-resistant, smooth and gap-free. Scope of application: high-end gift boxes, jewelry boxes, etc.

4. Local uv

Features: It is a process in which varnish is partially printed on the substrate and then cured with ultraviolet light to form a local bright effect; local bright, local matting, local frosting, local colorful, local refraction, local wrinkles, and local ice flowers. Scope of application: packaging boxes, hardcover album covers, business cards, etc.

5. Foaming

Features: Use microsphere foaming ink to print on paper or silk through screen printing, and then heat it to obtain a printing method with raised graphics or Braille reading materials; it has a concave and convex three-dimensional effect. Scope of application: paper, silk, Braille reading materials, etc.

6. Bump

Features: Green and environmentally friendly, adding layered richness and artistry, replacing traditional font colors, displaying core content, emphasizing parts, and showing three-dimensional and changeable effects. Scope of application: gift boxes, paper, cards, exquisite picture albums, etc.

7.Lamination

Features: Also known as over-gluing, the surface is covered with a transparent plastic film, forming a post-printing processing technology that combines paper and plastic; it has a certain degree of protection, protects the printing color from scratches, and increases the toughness of the printed matter. Scope of application: gift boxes, covers, advertisements, etc.

8. Sewing and threading

Features: The craftsmanship is simple, textured, and full of nostalgia, adding interest to the printed matter. It is an environmentally friendly craft. Scope of application: ancient thread-bound book binding, personalized creative gifts, special packaging gift boxes, greeting cards, invitations, etc.

9.Die cutting

Features: Change the single linear or flat form of printed matter to present a three-dimensional or curved effect, creating a variety of exquisite shapes. Scope of application: packaging boxes, covers, greeting cards, hang tags, invitations, advertising flyers, books, periodicals, albums, etc.

10. Glazing

Features: The surface is coated with a layer of colorless transparent paint, which after drying protects and increases the gloss of the printed matter; enhances the light resistance of the ink and its ability to protect against heat and moisture, beautifying the product. Scope of application: book album covers, packaging boxes, wall calendars, postcards, etc.

11.Embossed

Features: Showing different shades of patterns and textures, with obvious three-dimensional relief.

Scope of application: gift boxes, advertising, packaging boxes, etc.

12. Frosted

Features: A layer of transparent UV frosted ink is printed on a substrate with mirror gloss. After UV curing, a rough surface like frosted glass is formed; the pattern is exquisite, the three-dimensional effect is strong, the pollution is small, the efficiency is high, and the solvent and heat resistance are good. Scope of application: cards, packaging boxes, covers, etc.

13. Laser

Features: Utilizes the characteristics of the interaction between laser beam and material to process materials such as cutting, drilling, marking, and scribing; it has no contact with the surface of the material, is not affected by the elasticity and toughness of the material, and has high processing accuracy and fast speed. Scope of application: cards, packaging boxes, etc.

14. Leather hot stamping

Features: The leather surface has special natural patterns and the leather surface has a natural luster. In order to improve the performance of the leather, the leather surface needs to be decorated. Scope of application: high-end album covers, customized notebooks, special printed matter, high-end packaging gift boxes, etc.

15. Blister

Features: The flat plastic hard sheet material is heated and softened, then vacuum-adsorbed to the surface of the mold, and then formed after cooling; improves product image and price, protects products, facilitates display, facilitates sales, and has good aesthetics. Scope of application: plastic packaging, lighting, etc.

16. Brush the edges

Features: Post-printing process for processing the sides and micro-edges of printed matter. There are three categories: rolled gold edge, spray color and silk screen printing. Scope of application: business cards, books, etc.